When it’s time to purchase new commercial dishwashers for your school’s foodservice operation, try not to become overwhelmed by all the choices. Today’s commercial dishmachines come with technological advances designed to create efficiency for your dishroom and provide financial benefits as well as improved sustainability. Consider these commercial dishwasher innovations and decide which options are best for you.

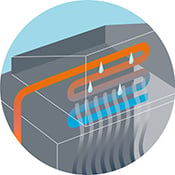

Ventless Energy Recovery

This feature is available on every size of high-temperature commercial dishwasher and can significantly decrease your operation’s utility and installation costs. Here’s what you need to know: Ventless energy recovery technology condenses steam and recycles heat from the wash chamber to bring incoming cold water temperatures up to 110 degrees, so the machine doesn’t have to work as hard to reach its required 180 degrees for sanitization. The result? Less energy is needed to operate the machine and less steam is emitted into the dishroom, making working conditions more comfortable for your employees. And, because the steam is condensed and removed from the chamber, a vent hood or direct venting are not required - saving over $3,500 on new installations.

This feature is available on every size of high-temperature commercial dishwasher and can significantly decrease your operation’s utility and installation costs. Here’s what you need to know: Ventless energy recovery technology condenses steam and recycles heat from the wash chamber to bring incoming cold water temperatures up to 110 degrees, so the machine doesn’t have to work as hard to reach its required 180 degrees for sanitization. The result? Less energy is needed to operate the machine and less steam is emitted into the dishroom, making working conditions more comfortable for your employees. And, because the steam is condensed and removed from the chamber, a vent hood or direct venting are not required - saving over $3,500 on new installations.

Drain Water Energy Recovery

Look for this technology when considering a conveyor-type dishmachine. For instance, the Hobart CL conveyor type dishwasher with Drain Water Energy Recovery (DWeR) reduces water usage by 90 percent. How does it work? The Advansys DWeR process captures heat energy from the drain water and uses it to increase the temperature of incoming cold water to 110 degrees, so the booster heater has less work to do to reach the required 180 degrees for proper sanitization. The hot drain water is cooled below 140 degrees, which also eliminates the need for added water for drain tempering. DWeR technology makes smart use of water and energy that would otherwise—you guessed it—just go down the drain, saving up to $1,350 on water and energy per year.

Look for this technology when considering a conveyor-type dishmachine. For instance, the Hobart CL conveyor type dishwasher with Drain Water Energy Recovery (DWeR) reduces water usage by 90 percent. How does it work? The Advansys DWeR process captures heat energy from the drain water and uses it to increase the temperature of incoming cold water to 110 degrees, so the booster heater has less work to do to reach the required 180 degrees for proper sanitization. The hot drain water is cooled below 140 degrees, which also eliminates the need for added water for drain tempering. DWeR technology makes smart use of water and energy that would otherwise—you guessed it—just go down the drain, saving up to $1,350 on water and energy per year.

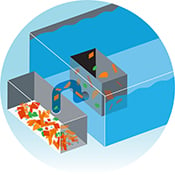

Automatic Soil Removal

While money-saving innovations are important to any K-12 foodservice environment, dishmachine features that save operators time on the front end are also in demand. If your team is spending a lot of time pre-rinsing and pre-scrapping before the ware items even make it into the machine, this technology will reduce that effort significantly. Automatic Soil Removal (ASR) pumps food soils out of the wash tank, so wash water stays cleaner longer. You can do less pre-scrapping and still have fewer wash water changes. It also minimizes the chance of rewashing, not to mention improving overall results. So, when you’re considering which replacement dishwasher to purchase, look for the ASR feature. Fewer tank fills will result in water conservation as well as energy savings - saving up to $500 per year on water, energy, and chemicals.

While money-saving innovations are important to any K-12 foodservice environment, dishmachine features that save operators time on the front end are also in demand. If your team is spending a lot of time pre-rinsing and pre-scrapping before the ware items even make it into the machine, this technology will reduce that effort significantly. Automatic Soil Removal (ASR) pumps food soils out of the wash tank, so wash water stays cleaner longer. You can do less pre-scrapping and still have fewer wash water changes. It also minimizes the chance of rewashing, not to mention improving overall results. So, when you’re considering which replacement dishwasher to purchase, look for the ASR feature. Fewer tank fills will result in water conservation as well as energy savings - saving up to $500 per year on water, energy, and chemicals.

Complete Delime with Booster Guard

Are you deliming your dishmachine and booster enough? Is your staff doing it safely, correctly, and effectively? Deliming is important to maintaining the performance of your dishwasher and should never be a guessing game. Hobart’s exclusive Complete Delime with Booster Guard notifies you when it's the right time to delime, then automatically doses delimer into the machine. This prevents excessive dosing, and at the same time reduces the handling of chemicals, making it safer for your staff. Booster Guard also injects delimer directly into the booster, preserving machine life and helping to prevent premature booster failure - saving $250 in chemicals per year to $5,000 on a potential new booster.

Are you deliming your dishmachine and booster enough? Is your staff doing it safely, correctly, and effectively? Deliming is important to maintaining the performance of your dishwasher and should never be a guessing game. Hobart’s exclusive Complete Delime with Booster Guard notifies you when it's the right time to delime, then automatically doses delimer into the machine. This prevents excessive dosing, and at the same time reduces the handling of chemicals, making it safer for your staff. Booster Guard also injects delimer directly into the booster, preserving machine life and helping to prevent premature booster failure - saving $250 in chemicals per year to $5,000 on a potential new booster.

ENERGY STAR® Qualification

To further promote your operation’s sustainability efforts, look for the ENERGY STAR® logo. Why is this important? According to EnergyStar.gov, commercial dishwashers that are ENERGY STAR certified are, on average, 40 percent more water and energy efficient than regular models. All Hobart CleN conveyor-type and Advansys door-type commercial dishwashers are ENERGY STAR certified. Remember that your ENERGY STAR equipment purchase may also qualify for rebates. Eligible commercial dishmachines can have incentives as high as $2,700. Check the ENERGY STAR website for more details.

To further promote your operation’s sustainability efforts, look for the ENERGY STAR® logo. Why is this important? According to EnergyStar.gov, commercial dishwashers that are ENERGY STAR certified are, on average, 40 percent more water and energy efficient than regular models. All Hobart CleN conveyor-type and Advansys door-type commercial dishwashers are ENERGY STAR certified. Remember that your ENERGY STAR equipment purchase may also qualify for rebates. Eligible commercial dishmachines can have incentives as high as $2,700. Check the ENERGY STAR website for more details.

Operator Ergonomics & Cleaning

Commercial dishwasher innovations may be equipment-based but they can also directly benefit the operator. Since staffing is always a big part of managing a foodservice operation, think about purchasing a dishmachine that contributes to operator satisfaction. Look for easy-to-read controls, ergonomically designed handles and features that make cleaning a breeze.

Choosing a replacement dishwasher for your K-12 kitchen is simple when you know the latest innovations and which ones are the priorities for your foodservice program. Use this guide when deciding which model to purchase and remember a few quick takeaways: The Hobart Advansys Ventless AM16 and CL conveyor type models can provide big cost savings—as much as $5,000 in the first year and up to $1,500 every year after. Plus, ENERGY STAR® certification helps ensure noticeable decreases in utility bills, which helps the bottom line AND sustainability initiatives.

Ready to learn more? Contact your local Hobart sales representative to find out which dishwasher would fit best into your school’s dishroom. They can also create a customized energy audit to show the savings you could experience with a new machine, making the switch that much easier.

%20.jpg)