Commercial dishwashers are an important part of any foodservice operation, whether large or small. Automatic dishmachines contribute in a big way when it comes to labor efficiency and cost savings. And, perhaps the most important contribution is performance; after all, the serving pieces, prep ware, and glasses must be spotless and sanitized.

However, there’s an element you should be aware that is often overlooked when considering the cost of operating your dishmachine—

Drain Water Tempering

This term refers to the process of cooling drain water (or wastewater) as it exits the dishwasher.

Why is it important?

Drain water tempering is defined in the national plumbing code and has been adopted by many cities and municipalities to help protect the integrity of drain lines. The temperature of the water leaving a dishwasher must be cooled to 140 degrees Fahrenheit or below so it’s not too hot when entering a drainage or sewage system. Water that is hotter than 140 degrees can degrade pipes and cause leaks in the drain lines.

Step 1

If you’re concerned about how drain water tempering may affect your foodservice operation, the first step is to know your plumbing codes. Do some online research and discuss the issue with a licensed plumber.

Step 2

Next, make sure the drain water from your commercial dishwasher is properly cooled before entering the drain system. This is important because it’s likely repairs to leaky drain lines will cost more than keeping your wastewater cooled to the correct temperature.

How it works

By now you’re probably wondering how the drain water tempering process works. In most cases, cold water is added to the drain water as it is exiting the dishwasher. The method can vary; some solutions use electrically actuated technology which requires a power source to open and close a cold-water valve. Other systems consist of a variably designed mechanical cold-water valve which works without the need for an additional power source.

If you determine drain water tempering is required, find out if your commercial dishwasher manufacturer offers a drain water tempering kit (drain water tempering kits are available for all Hobart dishmachines). A professional installation is recommended and once the kit is operational, a cold-water valve will automatically add cold water to the waste water when it starts to drain at the end of a cycle.

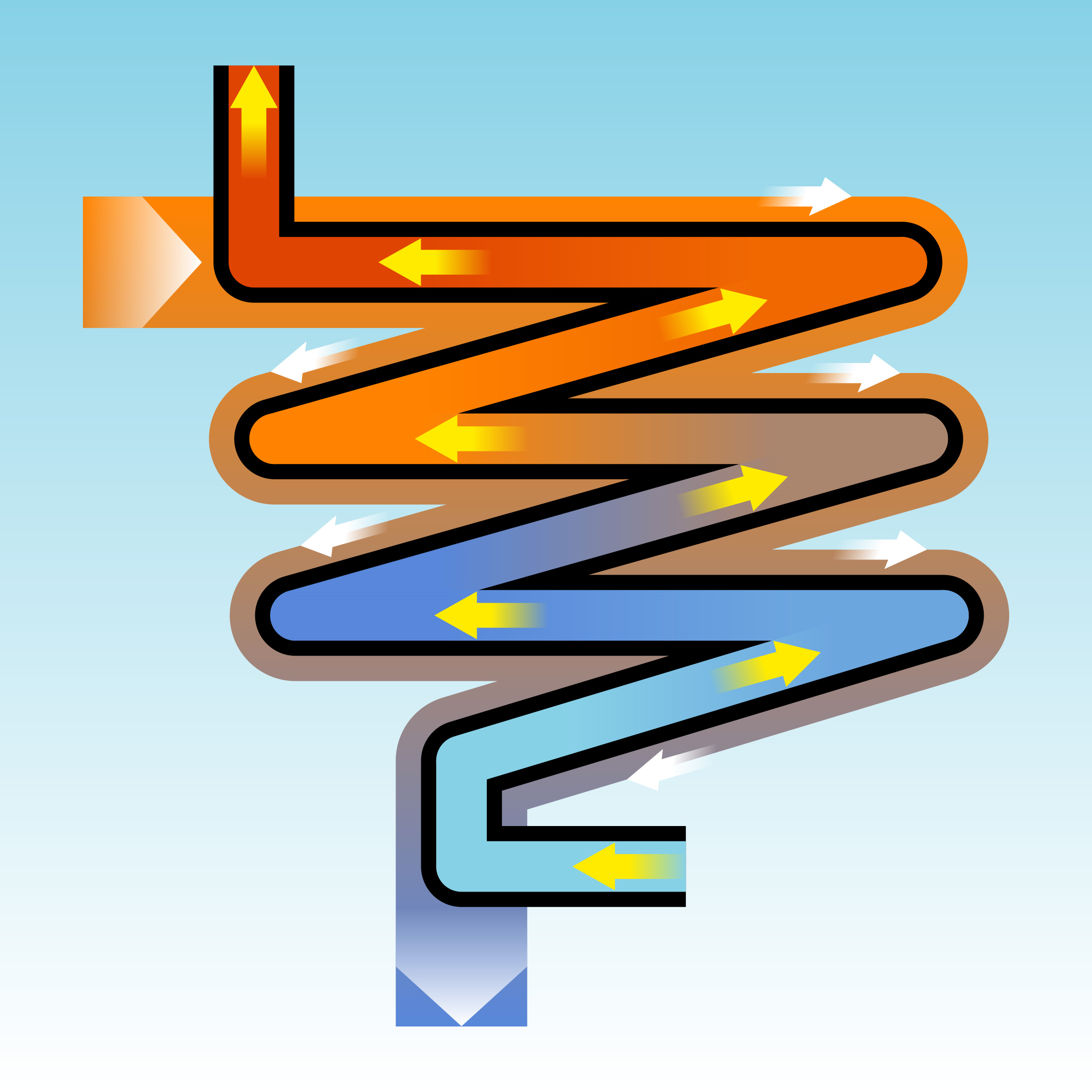

Technologies are also available that reduce the reliance on a tempering kit. The Hobart Advansys™ CLeN Conveyor Type dishwasher packs a punch when it comes to water and energy saving technologies. This dishmachine comes with the money-saving Drain Water Energy Recovery technology (or DWeR). DWeR is an exciting innovation that captures the heat from the hot wastewater to increase the temperature of incoming water from a cold-water line. Drain water is cooled below 140 degrees, reducing the amount of tempering water needed by up to 90%, saving a lot of water and money.

Whether you opt for installing a drain water tempering kit or purchase a machine with built-in drain water tempering technology, remember to keep your foodservice operation compliant with plumbing codes.

And, remember that commercial dishwashers are not the only pieces of equipment that produce hot wastewater. Check your operation for other equipment that may require a drain water tempering process, such as boilers, humidifiers, and other automatic cleaning equipment.

Contact Hobart at 888-4HOBART if you have any questions and/or would like to learn more about the installation of a drain water tempering kit.

.png)

%20proc%20%20(1).jpg)