By their very nature, kitchens are hot. With all the cooking that goes on, staff members constantly moving around, and equipment putting out heat, kitchens are an intensely hot place to work in. But there’s another hot back-of-house location that’s all too frequently overlooked — the dishroom. With its constant combination of steam and hot water, the dishroom can be an uncomfortable and physically demanding place to work in. Making your dishroom more comfortable can help with employee retention and, by using Ventless Energy Recovery, it can help with your bottom line.

What is Ventless Energy Recovery?

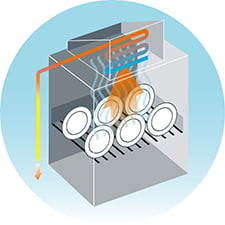

Simply put, Ventless Energy Recovery is a technology available on commercial dishwashers that recovers energy from the exhaust heat from the machine and recycles it. Here’s how it works: Steam from the wash and rinse cycles is condensed out of the air from the wash chamber. The heat energy from the steam preheats cold inlet water for the booster, thus reducing the energy needed to heat the sanitizing rinse. By removing steam while it’s still in the dishwasher, heat and humidity in the dishroom are reduced and the need for a vent hood is eliminated. On larger, flight-type and conveyor machines, energy from the exhaust air is used to heat the wash tank and blower dryer air as well. As is it exhausted out of the machine, the air passes over an evaporative coil — similar to an air conditioner — which helps cool down the room temperature even further.

Simply put, Ventless Energy Recovery is a technology available on commercial dishwashers that recovers energy from the exhaust heat from the machine and recycles it. Here’s how it works: Steam from the wash and rinse cycles is condensed out of the air from the wash chamber. The heat energy from the steam preheats cold inlet water for the booster, thus reducing the energy needed to heat the sanitizing rinse. By removing steam while it’s still in the dishwasher, heat and humidity in the dishroom are reduced and the need for a vent hood is eliminated. On larger, flight-type and conveyor machines, energy from the exhaust air is used to heat the wash tank and blower dryer air as well. As is it exhausted out of the machine, the air passes over an evaporative coil — similar to an air conditioner — which helps cool down the room temperature even further.

How Can Ventless Energy Recovery Help Run Your Dishroom Better?

By using Ventless Energy Recovery to help reduce the amount of heat and steam that is output, the dishroom becomes a more pleasant working environment. That leads to increased productivity and helps keep your valued employees.

Hobart dishmachines with Ventless Energy Recovery offer other advantages as well. By not having to install a vent hood over the dishmachine, the significant costs involved in venting and ducting are eliminated. This can be especially helpful when it comes time to do renovations, or if the machine should ever have to be relocated.

Ventless machines run on a cold water line and greatly reduce the demand on a facility’s water heater. A Hobart ventless door-type machine running 250 racks per day can save over 400 therms in energy each year, which means an average cost savings of $370. When you add in an average cost of $3,500 to install a vent hood, that’s a major savings.

Hobart commercial dishwashers feature a number of other time- and labor-saving features, such as Automatic Soil Removal which reduces the amount of prescrapping and wash water changes needed, and automatic deliming which simplifies the task and helps keep your dishwasher running at peak performance. Talk to the dishroom experts at Hobart today and ask for a free cost of operations audit to see how much water, energy, and money a new ventless Hobart dishmachine could save your operation.

.png)

%20proc%20%20(1).jpg)