Anyone who’s had some experience with commercial dishwashers has heard about lime scale, and has probably even experienced the white scale building up inside the machine. Lime scale is the deposit of calcium and other minerals left behind when hard water evaporates. The hardness of water is measured in grains of minerals per gallon, and refers generally to calcium and magnesium. The higher the levels of calcium and magnesium in water, the harder the water. When hard water runs through appliances such as hot water heaters and dishwashers, the heat used in the process of running the appliances cause the minerals which are heat sensitive to precipitate out of the water. This can form a chalky film and eventually a caked-up, crusty layer in pipes, in the pump, inside the walls and on wash and rinse arms.

Alexander Anim-Mensah, engineering manager -- Warewash, ITW-Hobart Corp., provides information to help understand how scale, including limescale build up, can affect the performance of commercial dishwashers and how to mitigate the issues.

Q: Who should worry about lime scale build up?

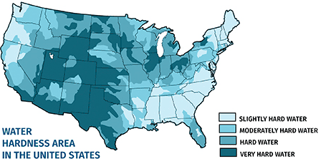

A: Lime scale build up on commercial dishwashers is the result of hard water running through the machine. Different parts of the country experience different water hardness levels, but almost every area has some amount of mineral deposits occurring naturally in the water.

Q: Why is it important to delime a commercial dishwasher?

A: There are basically three reasons why regular deliming practices are important. First, it improves the longevity of machine by preventing buildup that could cause corrosion. Secondly, deliming helps prevent the malfunctioning of key machine components such as sensors, valves, and pumps. Scale buildup in pumps causes them to work harder to push water through the valves, and too much build up leads to corrosion, all of which takes a toll on the overall performance of the machine. Therefore, keeping up with deliming helps maintain consistent wash quality by unclogging scale build up in the wash and rinse arms.

Q: How does the deliming process work in a commercial dishwasher?

A: Lime scale build up, which is mostly calcium and magnesium deposits left from hard water, is mostly alkaline by nature. Therefore, an acidic formula is needed to break up and dissolve the buildup. Commercial dishwashers are equipped with a deliming cycle, which runs a little differently than a regular wash cycle. During this cycle, deliming chemicals are added to the water and the solution made is circulated through the machine. It is important that a little heat is used in the early stage of the process as well, as the lime scale build up could contains fats and oils from leftover food particles bond with the scale. The hot water will release the fats and oils and allow the delimer to react with the scale to break it up and dissolve it in the water.

Q: What is the difference between a manual, semi-automatic and automatic deliming cycles?

A: Most commercial dishwashers are equipped with a deliming cycle, whether it’s manual, semi-automatic or fully automatic. In a manual cycle, the operator will look inside the machine his/herself to determine the level of buildup mostly on the heating element. When it’s necessary to run the deliming cycle, the operator will fill the tanks to the appropriate water level, add delimer, circulate the solution through the machine for a given time, and then drain it. Then the tank is filled back with fresh water, circulated run through another cycle to get rid of residual delime solution before it’s ready for a normal wash.

Commercial dishwashers with semi-automatic or automatic deliming function will alert the operator when it’s time to run the deliming cycle. Hobart’s Advansys line of commercial dishwashers include an autodelime function. In this case, it alerts the operator when it’s time to delime, and if the operator accepts to delime, the machine doses the right amount of delimer, circulates the deliming solution for a given time, drains deliming solution, rinses machine with fresh water and put the machine back in service. Hobart has other machines similar to the Advansys line which have a semi-automatic delime cycle. In this case all the operator has to do is to add the delimer when prompted.

Q: How often should the deliming cycle be run on a commercial dishwasher?

A: The frequency of deliming depends upon the hardness level of the water, the water temperature and how much water is cycled through the dishwasher each day. Generally, higher temperatures cause more of the temperature-sensitive hardness to precipitate out of the water as scale. This means with all things being equal, a machine operating at a lower temperature is expected to scale less than a higher temperature one. Also, water softeners can be added to commercial dishwashers to reduce the amount of lime scale build up, which can also reduce the frequency of deliming. This means water softening will increase productivity because of fewer shutdowns to delime machine.

Other factors also play a part in frequency of deliming. While deliming is good, excessive deliming and not following appropriate procedure could be bad for the machine, as most delimers are acidic and can harm the machine if not used properly. Moreover, some dishwashing chemicals could cause more hardness to precipitate as scale in addition to the heat produced scale.

When installing a commercial dishwasher with an automatic or semi-automatic deliming notification, the operator will program in the results of water hardness. The computer in the machine tracks the amount of water used and alerts the operator when it is time to run the deliming cycle. Deliming at the appropriate frequency, using the right delimer and dose and following the proper deliming procedure can improve the longevity of a commercial dishwasher.

.png)

%20proc%20%20(1).jpg)